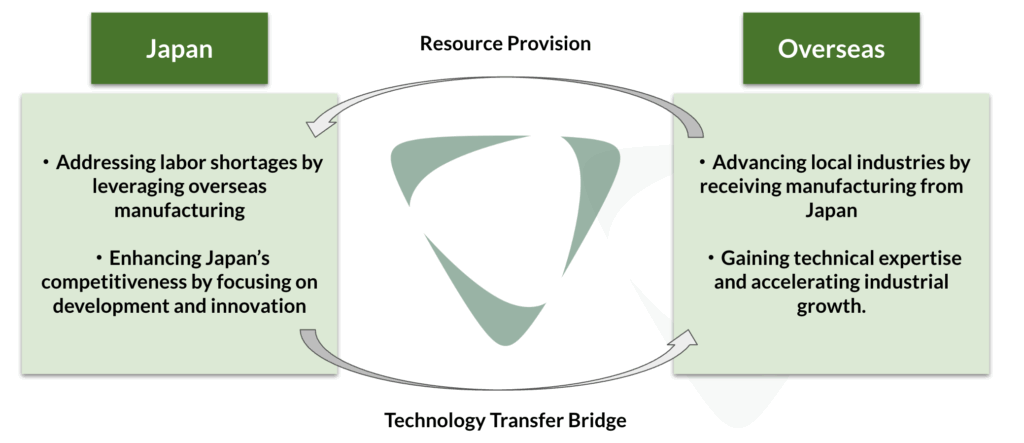

Our mission

Japan’s manufacturing faces critical challenges: an aging workforce and dwindling interest among younger generations, leading to business closures and rising costs. At SSK Global, our mission is to sustain Japan’s long-honed tradition of craftsmanship by forging new collaborations with overseas partners—and to pass this legacy to future generations.

Services

Strategic Procurement & Support

For decades ahead, we stand shoulder-to-shoulder with our clients: embracing new learnings, integrating cutting-edge technologies, and partnering with trusted manufacturers to carve out the future of manufacturing together.

Our experts offer procurement and manufacturing support, enhanced by on-site international staff to ensure comprehensive service—and bring manufacturing professionals directly into the process to deliver deeper value than conventional trading firms.

Procurement Assistance

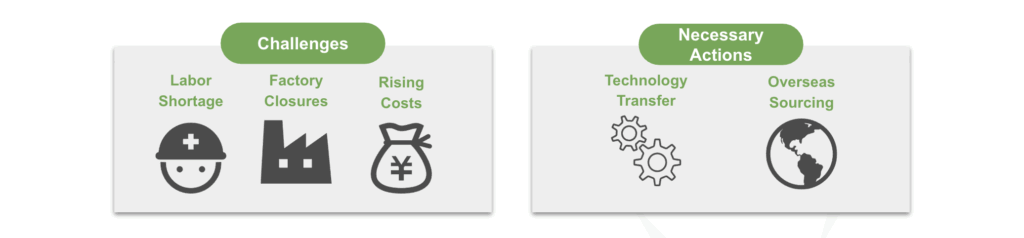

Procurement overseas is essential—but not easy.

We address core challenges by deploying professionals both in Japan and abroad:

Local experts fluent in Japanese handle all specialized communication—no need to worry.

Leveraging existing networks and local expertise, we provide high-level research and connection.

We manage start-up overheads using our team’s firsthand experience in initiating overseas transactions.

We align quality level at factory site and

Back-up with partners in Japan after delivery

We don’t stop at introductions—we advance further through our manufacturing support to transform client ideas into reality.

Network / Partners

We’ve extended our reach beyond simple procurement, aligning our capabilities with clients’ evolving demands:

- CNC milling

- steel, stainless, aluminum, plastic

- CNC turning

- steel, stainless, aluminum, plastic

- Surface & cylindrical grinding

- Small-diameter deep-hole machining

- Casting/forging + secondary processing

- Gear machining

- Laser cutting, bending, welding

- Surface treatments like galvanizing and anodizing

- Powder coating

- Frames

- Press forming

- Pipes, springs

- Tanks

- Injection molding

- Vacuum forming

- Custom machinery

- from design to assembly and delivery

- Assembly

- electrical and mechanical assembly units

Working Process

Our process is transparent, from site visits to delivery and aftercare:

Recommend ideal suppliers from our local network

Correct communication about requirements and remarks through our local staff

Japanese team arranges and leads inspections

Giving you confidence in local operations

Manufacturing experts assist with tooling choices and program setup

Our local staff check the quality with supply partner before shipping

Our Japan members will respond immediately

Partners in Japan can support quality back-up

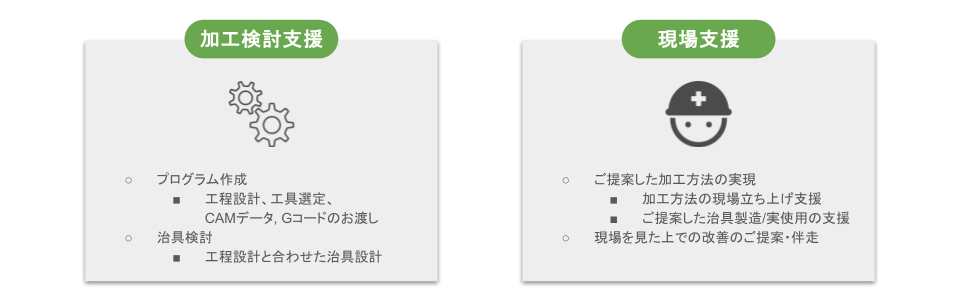

Advanced Machining Support

We know true manufacturing support goes beyond introductions. Leveraging our experience in managing overseas factories, we dive in to solve real-world challenges:

Tackle rising labor and energy costs while meeting annual cost-down targets

Support capacity expansion through outsourced programming and machining

Aging workforce demands succession, but time and resources for training are lacking

Members with hands-on experience in managing overseas machining companies—as well as those skilled in programming and actual machining—work closely with you to solve on-site challenges.

1. Achieving cost reduction through process improvement

2.Supporting capacity expansion through outsourcing of programming operations

1.Achieving cost reduction through process improvement

2.Supporting capacity expansion through outsourcing of programming operations

Our Expert Team

Our team comprises professionals experienced in launching overseas operations, machining, and quality control, working hand-in-hand from Japan and abroad to solve client challenges.

Yusei Shibata

Executive Officer, Sales Director

Built sales experience at a major machine tool trading company, then joined a manufacturing startup to support factory setup in Vietnam.

As the third-generation successor of vacuum forming tray maker Shisan Kogyo, returned to the family business and now leads the launch of SSK Global.

Kousuke Sakai

Executive Officer & Technical Director

Engaged in material development and overseas plant setup at a leading steel manufacturer.

Later turned around an overseas CNC factory and independently managed overseas operations.

Currently leads machining strategy and supplier development at SSK Global.

Bui Cong Thuong

Vietnam Operations Manager

Graduated from Hanoi University of Science and Technology.

Experienced in design, cost optimization, and quality assurance at a top Japanese Tier 1 supplier.

Has visited and audited dozens of local suppliers to build quality systems from scratch.

Norben Rejano

Philippines Operations Manager

Skilled in CNC machining, process design, and programming.

Supported turnaround of overseas plants and led production for both local and Japanese clients.

Offers end-to-end machining proposals including optimal tool selection.

Building the Future With You

SSK Global is committed to envisioning and creating new manufacturing paradigms alongside our clients—even amid challenges—so that valuable Japanese technologies endure and flourish globally.